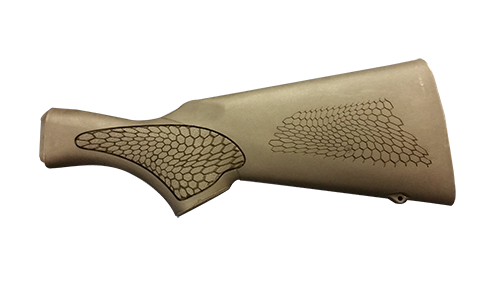

Z-Tech Advanced Technologies Inc. is among the world’s leading manufacturer of solid state, diode pumped, Nd:YAG, YV04, ytterbium-fiber, and Direct Diode laser cutting, engraving, marking and welding systems and source. Innovators in solution applications that include laser welding, laser cutting, laser marking, laser deep engraving, hermetic seam welding, micro machining, laser drilling, and trimming for the global Firearms, Plastic injection, Medical Device, Jewelry, Dental Laboratory, and General Industrial Sectors.

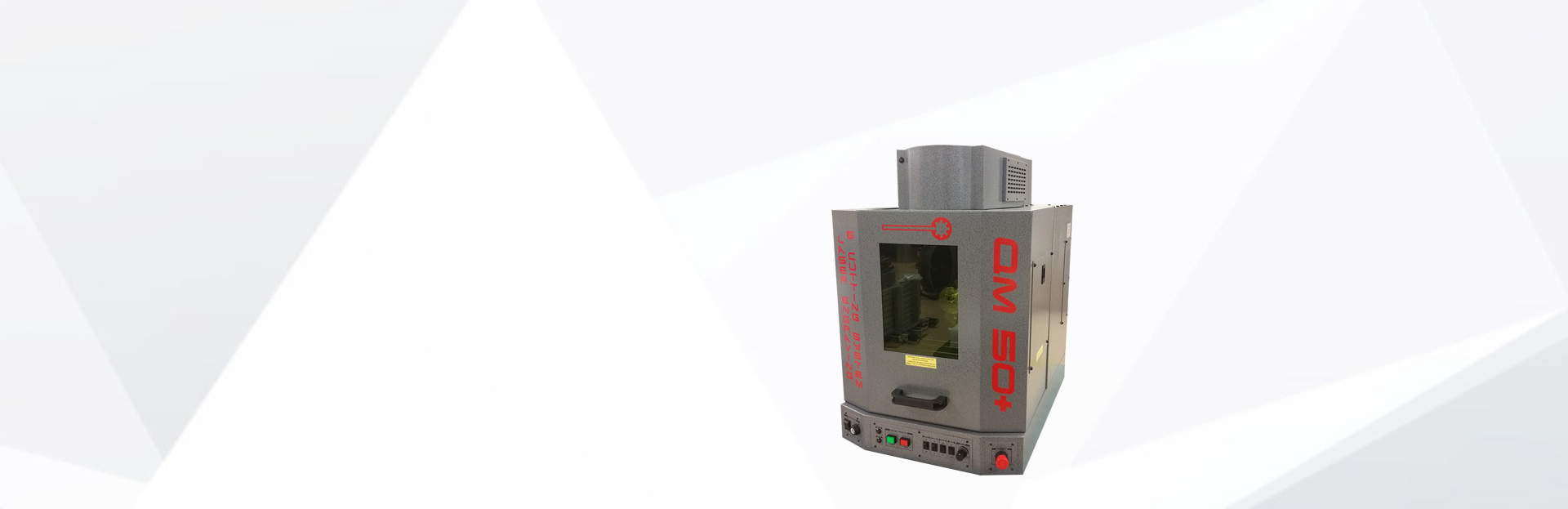

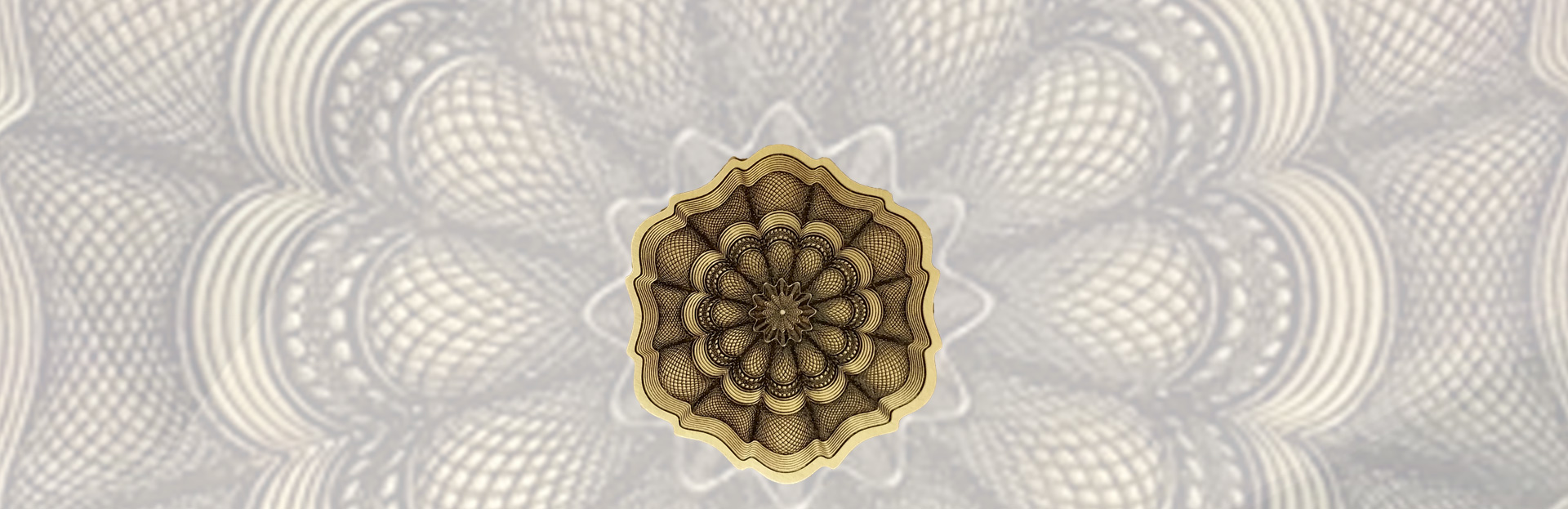

Q and IQ Series™ family of high power laser engraving, marking and cutting systems includes the QM Plus, QM, IQ, Q family of high power laser engraving and cutting systems offer a wide range of material processing including all metal alloys, such as tool steel, titanium, brass, copper, gold, silver, platinum, tungsten, and aluminum just to name a few as well as marble, granite, ceramics, zirconium, G10, carbon fiber, polymers, rubber, leather, glass, diamonds, ABS plastics and many more organic materials.

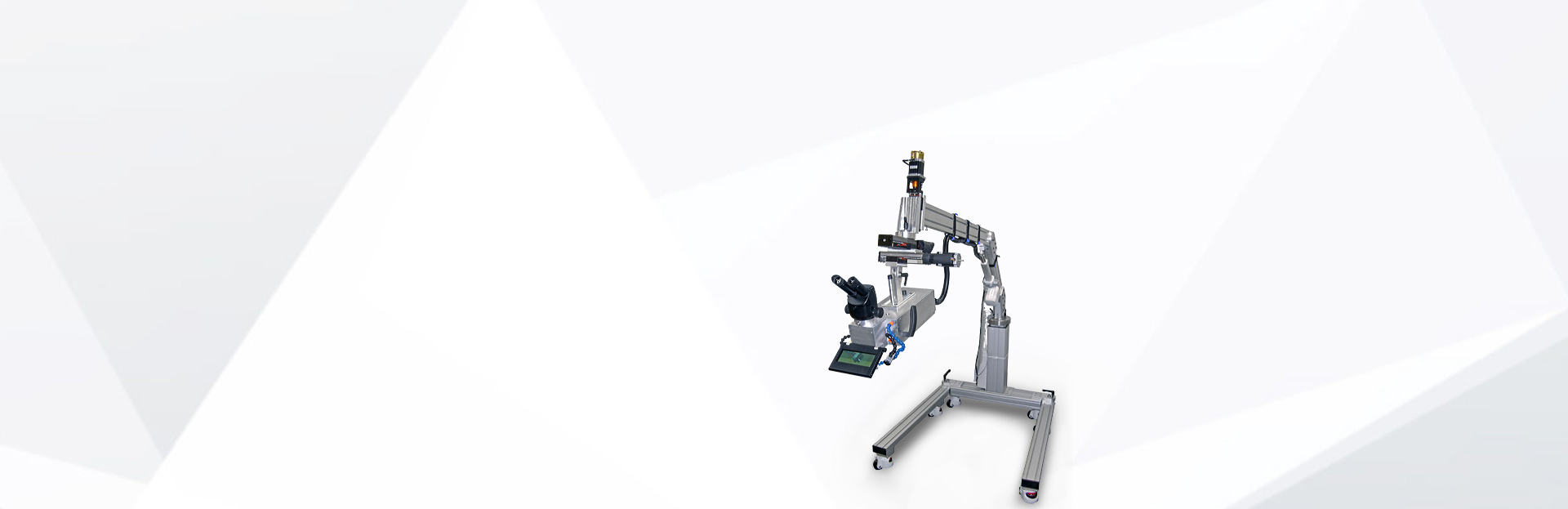

6V Series™ Pulsed laser welding machines from Z-Tech Advanced Technologies are the latest breed of the original lasers that revolutionized the way manufacturers think about laser welding. The 6V Series offers versatility, effectiveness and rapid return on investment necessary to compete in today’s manufacturing environment.

The latest generations of laser welding, engraving and cutting machines are currently the most advanced laser systems on the market featuring new and improved technologies such as Delicate-Weld resonator™ for welding on or near to heat sensitive materials such as color Gemstones in the jewelry industry, ceramic or acrylic in dental appliances, and thin or hollow cavities in Plastic Injection Molds etc… Another State-of-the-art feature is a True Automated Pulse Modulation (APM) This improves the welding process of metals such as 300 and 400 series, M2, D2, 17-4, P20, gold, platinum, palladium, chromium cobalt, nickel chrome, silver, copper, aluminum, titanium, Monel, Kovar, Nitinol and many others. Advances in beam dynamics, direct diode pumping, dynamic focusing and software development allows our laser engraving and marking systems to deliver the finest beam, power output efficiency , processing speed and the widest material processing materials.

The latest generations of laser welding, engraving and cutting machines are currently the most advanced laser systems on the market featuring new and improved technologies such as Delicate-Weld resonator™ for welding on or near to heat sensitive materials such as color Gemstones in the jewelry industry, ceramic or acrylic in dental appliances, and thin or hollow cavities in Plastic Injection Molds etc… Another State-of-the-art feature is a True Automated Pulse Modulation (APM) This improves the welding process of metals such as 300 and 400 series, M2, D2, 17-4, P20, gold, platinum, palladium, chromium cobalt, nickel chrome, silver, copper, aluminum, titanium, Monel, Kovar, Nitinol and many others. Advances in beam dynamics, direct diode pumping, dynamic focusing and software development allows our laser engraving and marking systems to deliver the finest beam, power output efficiency , processing speed and the widest material processing materials.

Z-Tech Advanced Technologies Inc. manufactures a full range of industrial welding, engraving, marking and cutting machines with an average power from 10W – 600W and peak power up to 10KW with or without CDRH Class 1 enclosures, Motion controls, weld monitoring and inert gas controlled environment.

Z-Tech Advanced Technologies Inc. builds the most robust laser welding, engraving, marking and cutting machines on the market and they are backed by the longest warranty in the industry in addition to our legendary training and 24/7 technical support service.